Shared by Khun Nontiwat Hutangkura, WHP and PL Installation and WHP Removal Project Manager at Chevron Thailand

Notes taken by Balltec Engineered Solutions and Alliance Sealand Equipment Solutions

As PM of WHP/PL Installation and WHP Removal, I’m so proud with my team, colleagues, OIC and subcontractors for all dedicated and disciplined hardworking during last 2023/24 campaign until we achieved unforgettable removal record of 25 WHPs and 4 topside reuses and PL installation in 438 days continuously with no LTI or any FAC at all. (Approx. 1.3 million man-hours that we worked and executed safely).

Innovations for Removal Operation

- Cut half jacket / full jacket lifting: Focused on operation, transportation, and loading-in.

- Choked slings vs. ILT / roll pinning: Bottom jacket removal was optimized through these approaches.

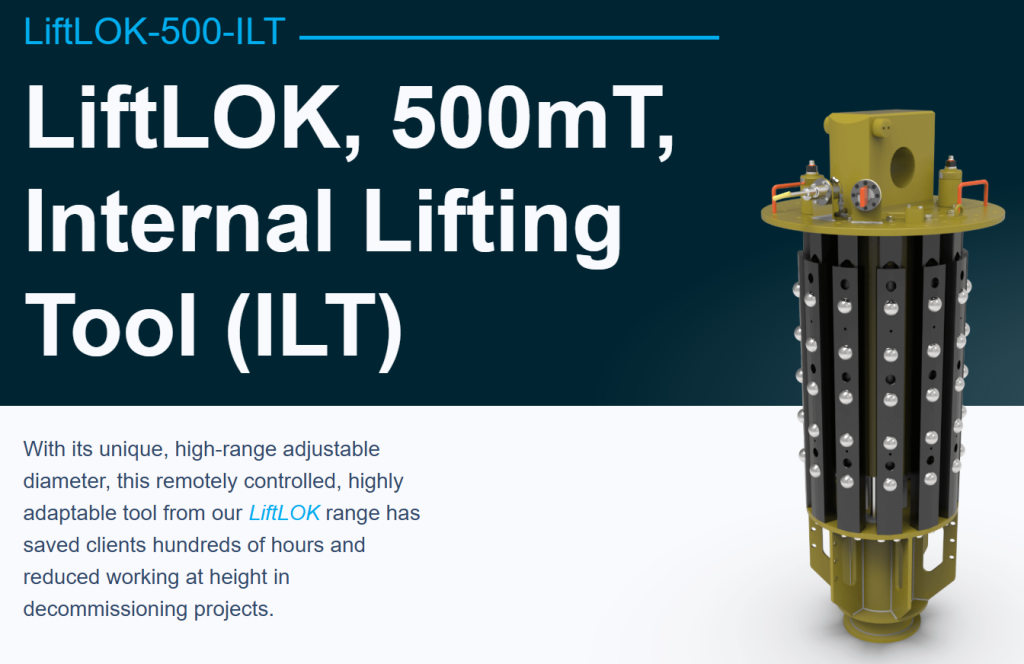

- Activated use of ILT (Internal Lifting Tool): Balltec’s newly fabricated 500MT ILT supported modular jacket lifts. Tri-plate setups enabled block transfers.

- Load-in methodology: Used side/stern load-ins, grillage setup, and barge rotation plans to minimize logistics.

- Dry and wet pipeline recovery: Executed without divers by deploying sea plug-enabled PRT tools.

- Hydraulic shackles: Enabled rigging of upper jacket tops without requiring crew to work at height.

- Shear cutter in firing line: Replaced slower guillotine and chop saw operations.

- Platform grouping: Reduced engineering complexity and prep time.

- Not-to-Exceed (NTE) topside weight limits: Controlled variation risks during lift planning.

- CSV pre-support: Cut down HLV deployment time during WHP removal.

- Padeye design optimization: Used boring rather than welding for padeye prep.

Balltec LiftLOK ILT 500MT tool used in modular jacket lifts.

Project Lessons Learnt

From the 2023/24 Campaign

- Sequence matters: Early familiarity with WHP/PL layouts was vital.

- Generic but flexible design: Allowed execution adaptability across multiple sites.

- Tool & spare availability: Tools like SPMT, IPC, PRT, DWS, and chop saws required robust logistics.

- Offshore readiness: Sustained campaigns needed crew rotation, vessel servicing, and internet access.

- Fabrication yard selection: Proximity helped reduce dismantling and re-rigging delays.

- Dynamic plan backups: Crucial for schedule protection.

- Unified mindset: “One Goal, One Team” culture drove safety and success.

For the 2024/25 Campaign

- Playbook knowledge transfer: Helped bring new OICs up to speed faster.

- Engineering completion 30 days prior to mobilization: Essential for offshore execution confidence.